-

Home

-

Vehicle Lift

-

Two Post

-

Four Post

-

Short platform

-

Long Platform

-

Heavy Duty

-

Motorcycle Lift

-

Lifting Table

-

Rolling Jack

-

-

More

MoreE28 | 18000LBS

Two independent columns

78 3/4"

Max Lifting Height

8 3/4"

Min Height

114 1/4”-129 5/8"

Drive-through width

55s

Lifting Time

130

Min Height

2000

Max Lifting Height

55

Lifting Time

2900-3300

Platform Length

With the maximum capacity being up to 18000lbs, it is especially suitable for lifting large Pick-ups, MPVs, Vans, medium buses and loaded vehicles.More

-

-

-

More

MoreE25 | 11000LBS.

Two independent columns

78 3/4"

Max Lifting Height

3 3/4”

Min Height

114 1/4”-129 3/4”

Drive-through width

25S

Lifting Time

110

Min Height

2000

Max Lifting Height

25

Lifting Time

2900-3300

Drive-through Width

With a maximum capacity of 5000kg(11000lbs), it is especially suitable for lifting large pickups, SUVs, MPVs, vans, small caravans, medium buses and light trucks; No more obstructions at your feet and let you and your tool cart move easier under the lifted vehicle.More

-

-

-

More

More62C | 11000lbs./13200lbs.

Two post lift with APS technology

74 3/4"

Max Lifting Height

3 3/4"

Min Height

113 1/8"

Drive-through width

35s

Lifting Time

100

Min Height

1900

Max Lifting Height

35

Lifting Time

3006

Drive-through Width

With APS technology (Accurate Parking System);One hand and one side operation.More

-

-

-

More

More62C | 7700lbs. /9300lbs.

Two post lift with APS technology

74 3/4"

Max Lifting Height

3 3/4"

Min Height

152 1/4" | 169 1/4"

Overall Height

113 1/8" | 118 3/4

Drive-through width

35s

Lifting Time

More95

Min Height

1900

Max Lifting Height

35

Lifting Time

0

Platform Width

0

Platform Length

2545/2698

Drive-through Width

-

-

-

More

MoreC12/C10/C9 | 12000LBS./10000LBS./9000LBS.

Spray BoothSpray BoothSpray Booth

74 3/4"

Max Lifting Height

3 3/4"

Min Height

111 1/2"

Drive-through width

55s

Lifting Time

95

Min Height

1900

Max Lifting Height

55

Lifting Time

2558

Drive-through Width

Clear floor design for easy movement of maintenance equipment under the raised vehicle;Simply push one button for lowering.More

-

-

-

More

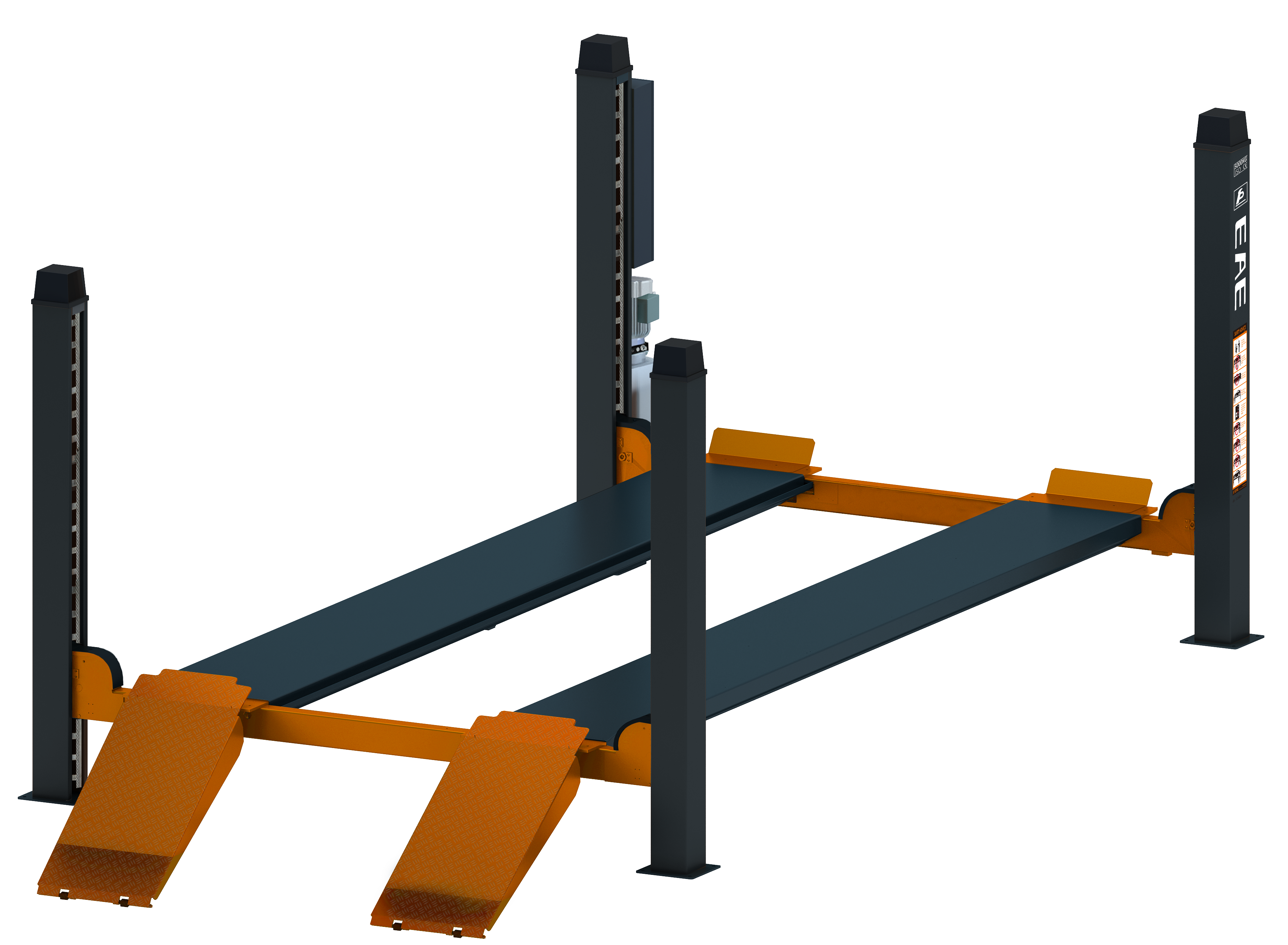

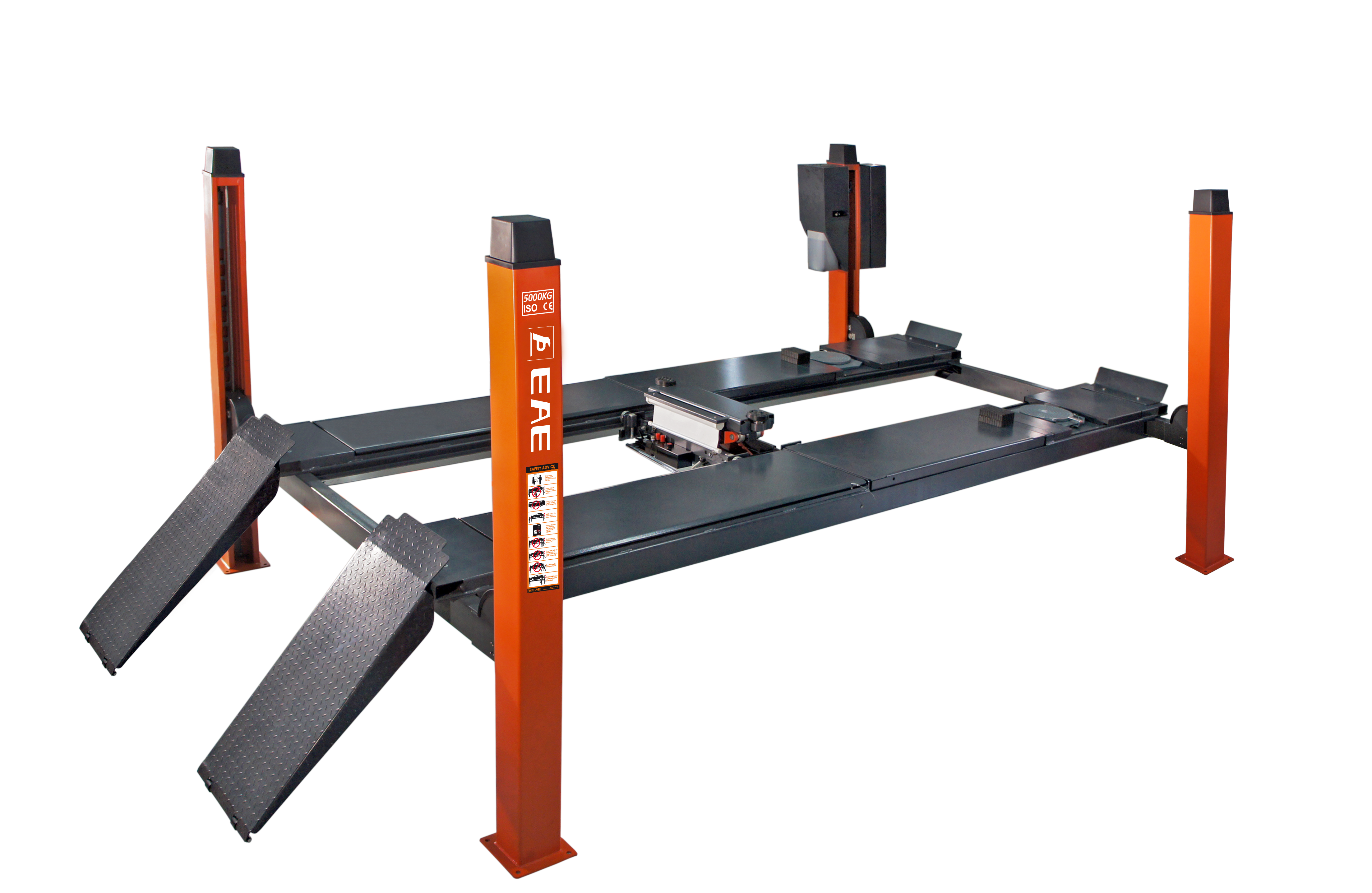

More6435BPD | 10000LBS. / 12000LBS.

Four Post Lift

8 7/8"

Max Lifting Height

7 1/8"

Min Height

192 1/8"

Platform Length

24 3/4"

Platform Width

65s

Lifting Time

180

Min Height

1830

Max Lifting Height

40

Lifting Time

630

Platform Width

5780

Platform Length

MOT four post lifts for Class IV&VII vehicles;Electrical Safety Lock Release System (E version).More

-

-

-

More

More6445P | 10000LBS.

Parking Lift

-

-

-

More

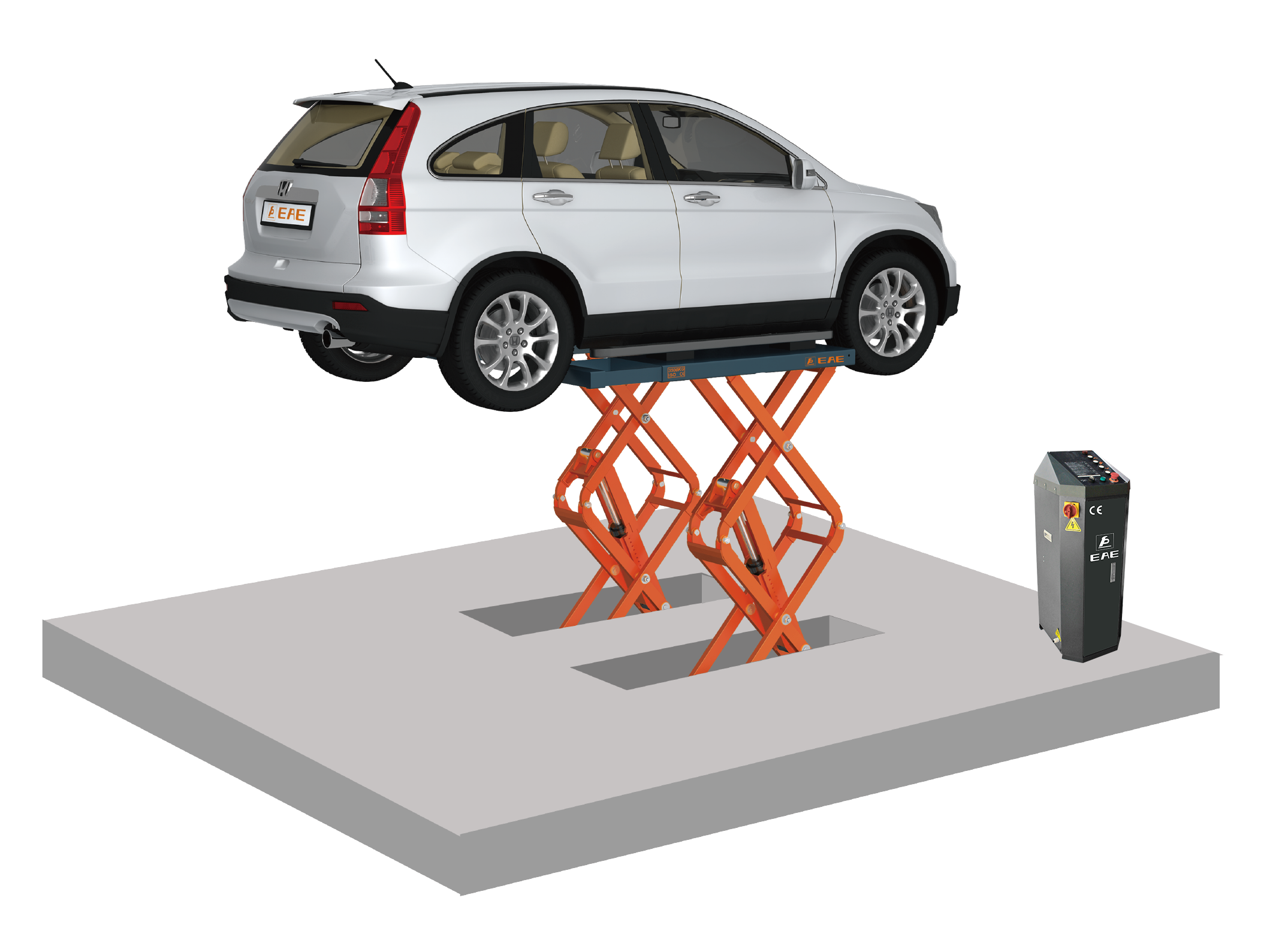

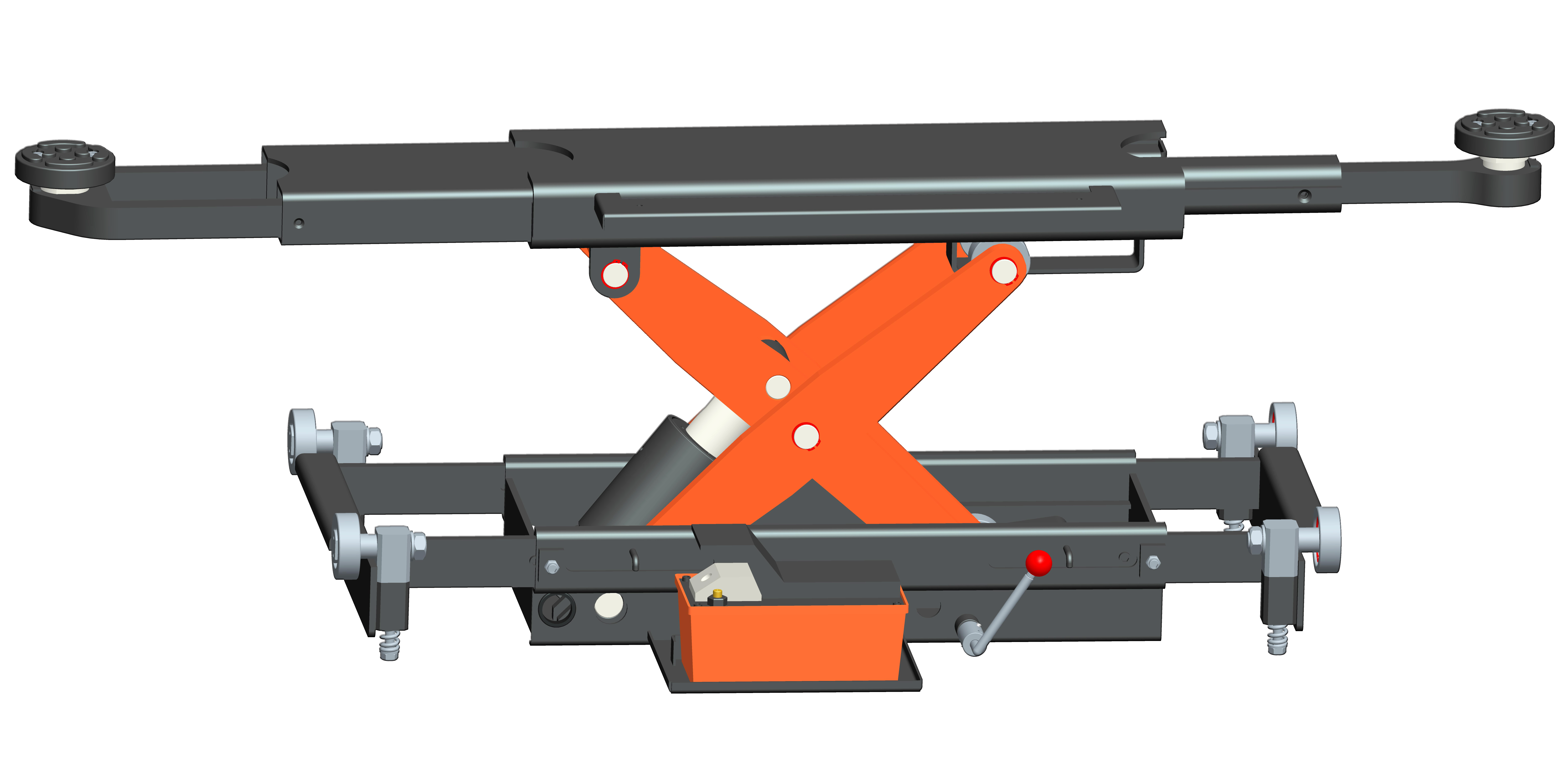

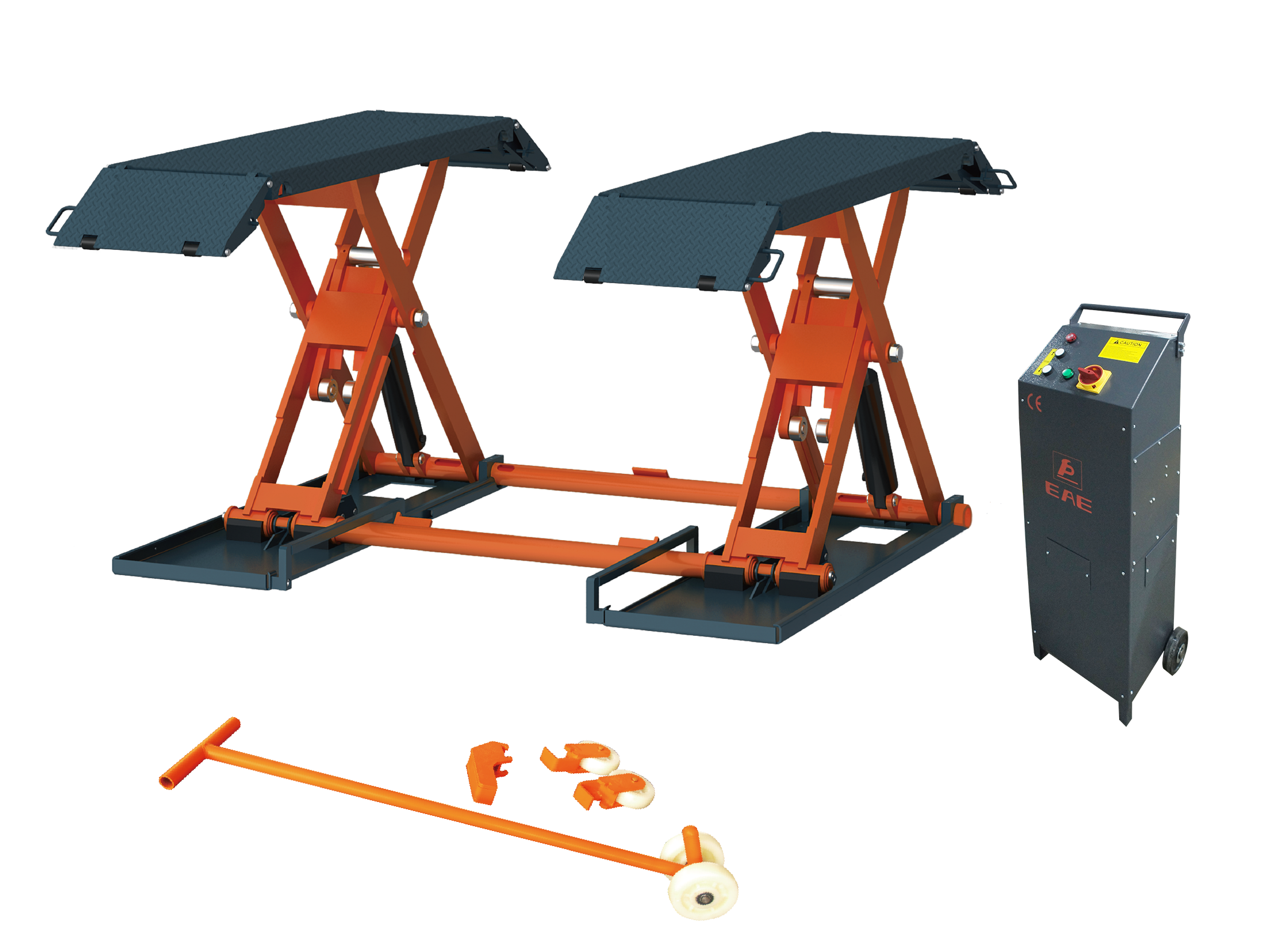

MoreMR35 | 3.5T

Mid Rise Scissor Lift

39 3/8"

Max Lifting Height

4 1/4"

Min Height

79 5/8"

Platform Length

30s

Lifting Time

110

Min Height

1000

Max Lifting Height

25

Lifting Time

460

Platform Width

2028

Platform Length

110mm drive-on height; Starting-Up plate, for easy raising from low point; Mobile or fixed mount design.More

-

-

-

More

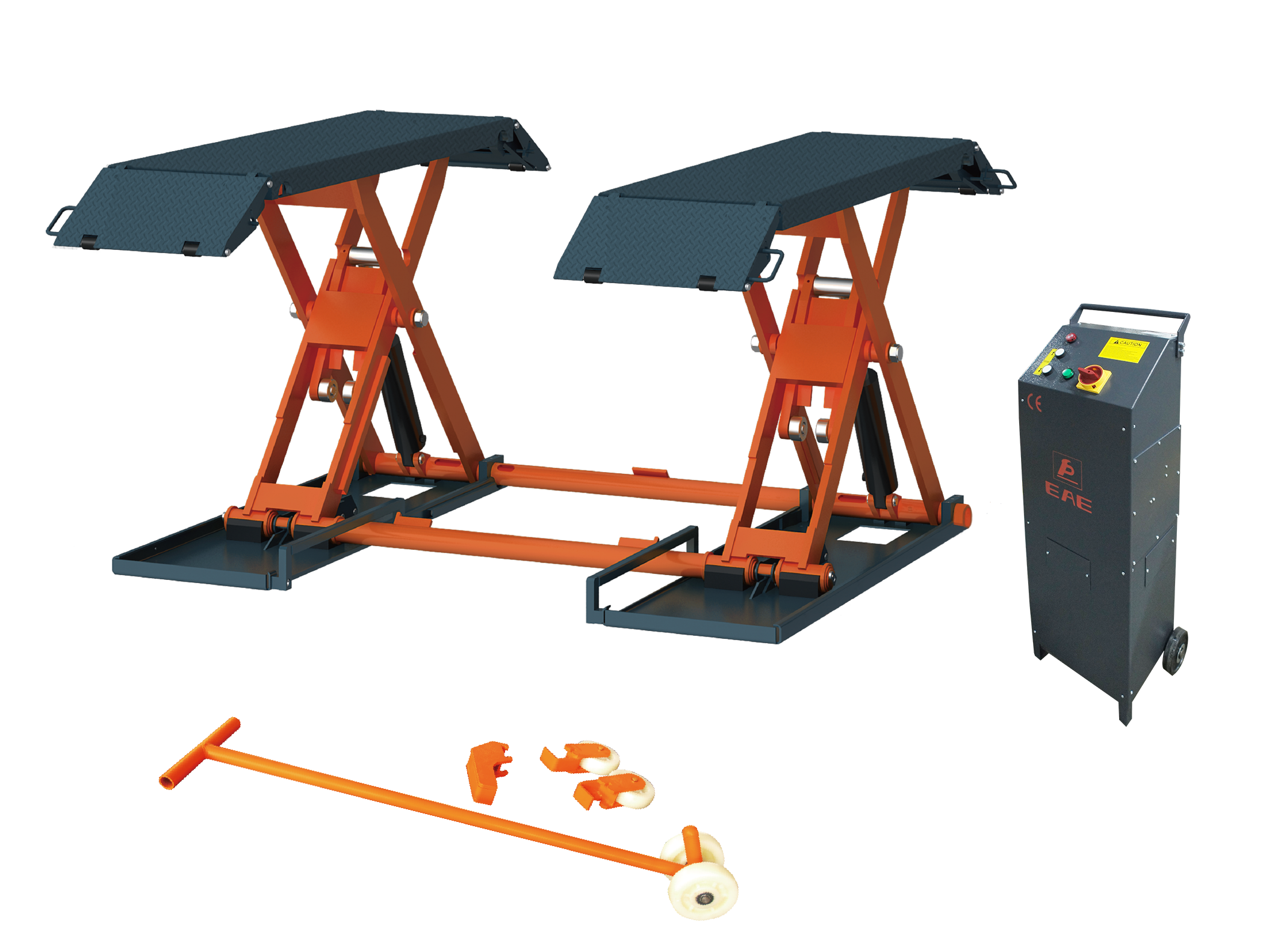

MoreMR30 | 3.0T

Mid Rise Scissor Lift

39 3/8"

Max Lifting Height

4 1/4"

Min Height

79 5/8"

Platform Length

30s

Lifting Time

105

Min Height

1000

Max Lifting Height

30

Lifting Time

460

Platform Width

2028

Platform Length

105mm drive-on height; Double safety ,hydraulic and mechanical; Mobile or fixed mount design.More

-

-

-

More

MoreTS6600 | 3.0T

Mid Rise Scissor Lift

47 1/4"

Maximum Height

5 1/4" + 1 1/4"

Minimum Height

2 3/8"

Platform length

40s

Lifting Time

135+30

Min Height

1200

Max Lifting Height

40

Lifting Time

1004

Platform Width

1550

Platform Length

Portable, easy to move; Double safety ,hydraulic and mechanical.More

-

-

-

More

MoreHX6 | 15000LBS.

Long Platform Scissor Lift

82 3/8"

Max Lifting Height

14 1/4"

Min Height

213 3/4"

Platform Length

25 3/4"

Platform Width

70s

Lifting Time

380

Min Height

2100

Max Lifting Height

50

Lifting Time

750

Platform Width

5424

Platform Length

6-8bar

Air Supply

Electrical levelling; Standard Wheel Free Lift.More

-

-

-

More

MoreHX50 | 12000LBS.

Alignment Scissor Lift

70 7/8"

Max Lifting Height

12 1/4"

Min Height

200 3/4"

Max. Length

25s

Lifting Time

310

Min Height

2130

Max Lifting Height

25

Lifting Time

650

Platform Width

5100

Platform Length

6-8bar

Air Supply

Max. lifting height 1800mm above floor; 5100mm long flat runways for general service use; Infrared synchronization protection system.More

-

-

-

More

More6603 Series | 10000LBS./12000LBS.

Alignment Scissor Lift

81 1/8"

Max Lifting Height

14 1/4"

Min Height

213 7/8"

Platform Length

50s

Lifting Time

360

Min Height

2060

Max Lifting Height

50

Lifting Time

610

Platform Width

4800/5100

Platform Length

5000kg lifting capacity; 5100mm Max. Platform Length; Automatic Leveling System; Standard Wheel Free Lift.More

-

-

-

More

More6604 Series | 8800lbs.

Low Profile Scissor Lift

74 3/4"

Maximum Height

7 1/16"

Minimum Height

60s

Lifting time

196 7/8"

Platform Length

7 1/8"

Platform width

180

Min Height

1900

Max Lifting Height

60

Lifting Time

660

Platform Width

5000

Platform Length

4000kg lifting capacity; 180mm Drive-on height; Surface installation, no concrete works needed ramps included; Standard Wheel Free Lift.More

-

-

-

More

MoreLX35 | 7700LBS.

Low Profile Scissor Lift

72 5/8"

Max Lifting Height

5 1/2"

Min Height

55s

Lifting Time

177 1/4"

Platform Length

26 3/4"

Platform Width

140

Min Height

1850

Max Lifting Height

55

Lifting Time

680

Platform Width

4500

Platform Length

Long slip plate and adjustable turntable positions for alignment use;3500kg lifting capacity; 140mm Drive-on height;Add-On Wheel Alginment runway kit.More

-

-

-

More

MoreHDM Series | 18000LBS./22000LBS.

Heavy Duty Mobile Column

70 7/8"

Maximum Height

19 3/4" - 49 1/4"mm

Applicable Tire Diameter

48

Maximum Columns

80s

Lifting Time

159

Min Height

1800

Max Lifting Height

85

Lifting Time

500-1250

Accommodates Tire Diameter

18000LBS./22000LBS. capacity per column; Wireless Communication; STM32 microchip technology in the control system; Communicate wirelessly by WLAN or be connected by cables.More

-

-

-

More

MoreMLH10/MLH10D | 2200LBS.

Heavy-duty Motorcycle Lift

47 1/4mm

Max Lifting Height

7 5/8"

Min Height

30s

Lifting Time

85 5/8"

Platform Length

40 3/4"

Platform width

160

Min Height

1200

Max Lifting Height

30

Lifting Time

800+240

Platform Width

2000

Platform Length

Hydraulic driven system, smooth running;Applicable to motorcycles, ATVS, lawn mower etc.More

-

-

-

More

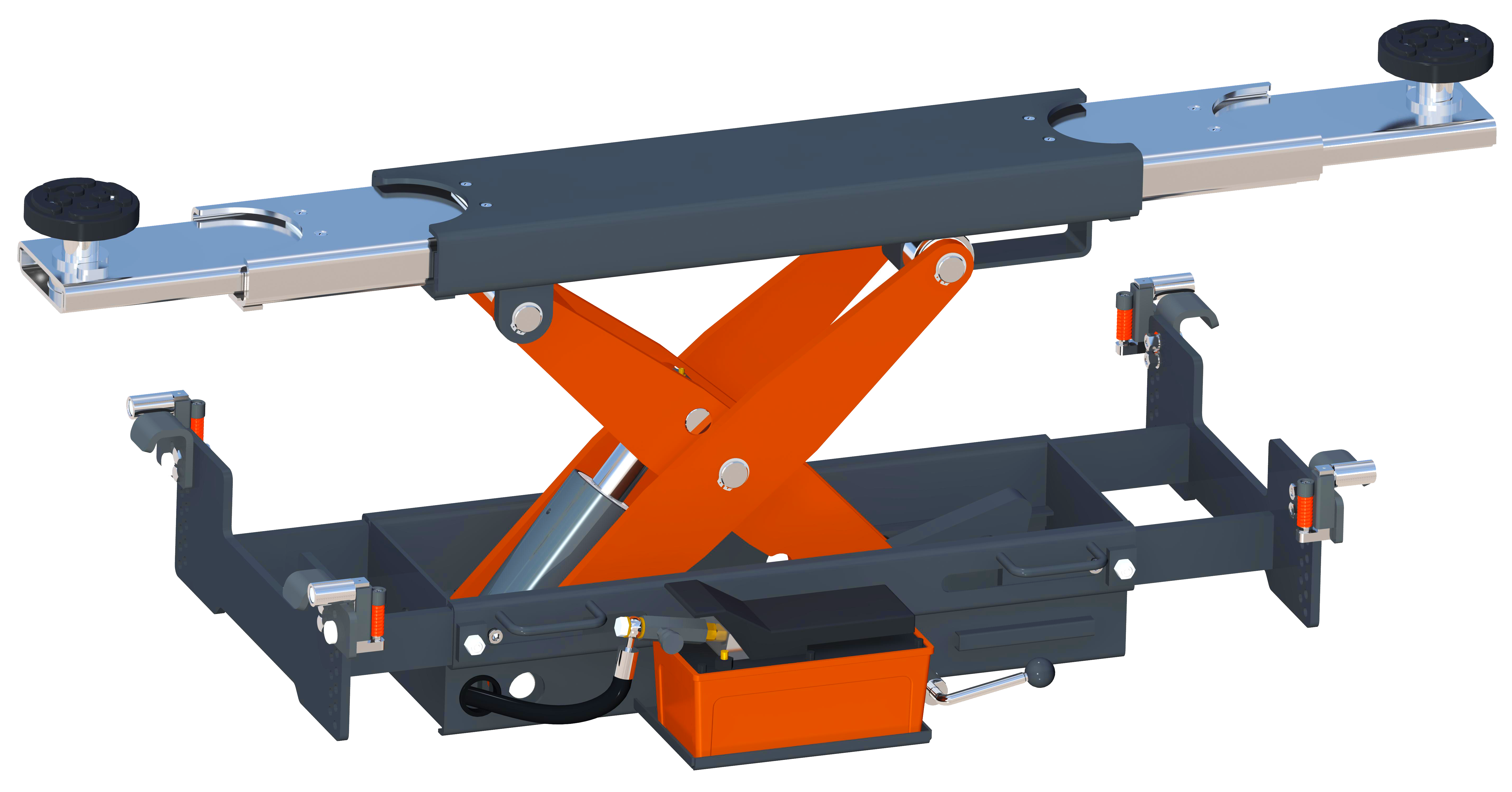

MoreMS12MF | 3000LBS.

Hydraulic Mobile Lifting Table

71 1/4"

Max Lifting Height

68 1/2"

Platform Length

31 1/2"

Platform Width

45s

Lifting Time

800

Min Height

1810

Max Lifting Height

45

Lifting Time

800

Platform Width

1741+325

Platform Length

This mobile lifting table is designed for dismantling and fixing batteries of electric vehicles as well as engine, gearbox, drive axle, fuel tank,suspension, bracket and chassis components of traditional vehicles.More

-

-

-

Company

-

Service and Support

-

Manufacturers Approvals

-

FAQ

-

News

Contact